StrictSprayPlus

No more skips with Agrifac’s PWFM system

StrictSprayPlus delivers absolute control over spray distribution and crop coverage, making sure every drop hits the right spot. By combining individual nozzle control with a consistently stable spray pressure, Agrifac ensures one clear result: the right amount of product, everywhere in the field, with the right droplet size, every time. This intelligent spraying system makes every droplet count. It boosts efficacy, minimizes overlap, reduces waste and helps growers achieve the best possible crop protection results.

Rapid pulsing up to 100Hz

Rapid pulsing up to 100Hz

While pulse width modulation (PWM) systems were originally developed to increase work rates, their true strength lies in enhancing accuracy and reducing input waste.

Traditional spraying applies a uniform rate across the entire field based on average crop needs. In reality, this often leads to over-application in some areas and under-application in others, causing uneven coverage and unnecessary product use.

Agrifac addresses this challenge with StrictSprayPlus, our advanced Pulse Width Frequency Modulation (PWFM) system. By pulsing each nozzle up to 100 times per second, StrictSprayPlus delivers a consistent spray pattern and flow rate, regardless of changes in speed, turning or terrain. The result? Optimized application, improved efficacy, smarter use of your inputs and no more skips.

Realize large savings, relatively easy

Realize large savings, relatively easy

Band spraying is a targeted spraying method for crops grown in rows. By spraying only a defined row instead of the full surface, inputs are reduced while maintaining effective crop protection, especially in early growth stages when the crop does not yet fully cover the soil.

The application rate is set by adjusting for the effective working width per nozzle and the row spacing, with boom height and nozzle angle influencing the final outcome. This precision approach can be used on the rows for fungicide or insecticide applications or between the rows for herbicide applications. Depending on the crop and row spacing, band spraying can deliver substantial savings compared to full field spraying.

With Agrifac’s StrictSprayPlus, band spraying is taken to the next level through accurate nozzle control and stable spray patterns.

Individual nozzle control

Individual nozzle control

With StrictSprayPlus, each nozzle is controlled independently. Every nozzle can open, close and adjust its output exactly when needed. This eliminates unnecessary overlap and ensures that every square inch of the field receives precisely the correct dose.

When turning, the nozzles on the outside of the boom travel faster than those on the inside. StrictSprayPlus automatically compensates for this difference nozzle by nozzle. The result is a perfectly even application rate across the entire boom, even in tight curves and complex field shapes.

StrictSprayPlus separates application rate from spray pressure. That means spray pressure stays stable throughout the operation, regardless of speed changes or section switching. A constant pressure ensures a consistent droplet size, delivering uniform crop coverage and reliable spray quality across the entire field.

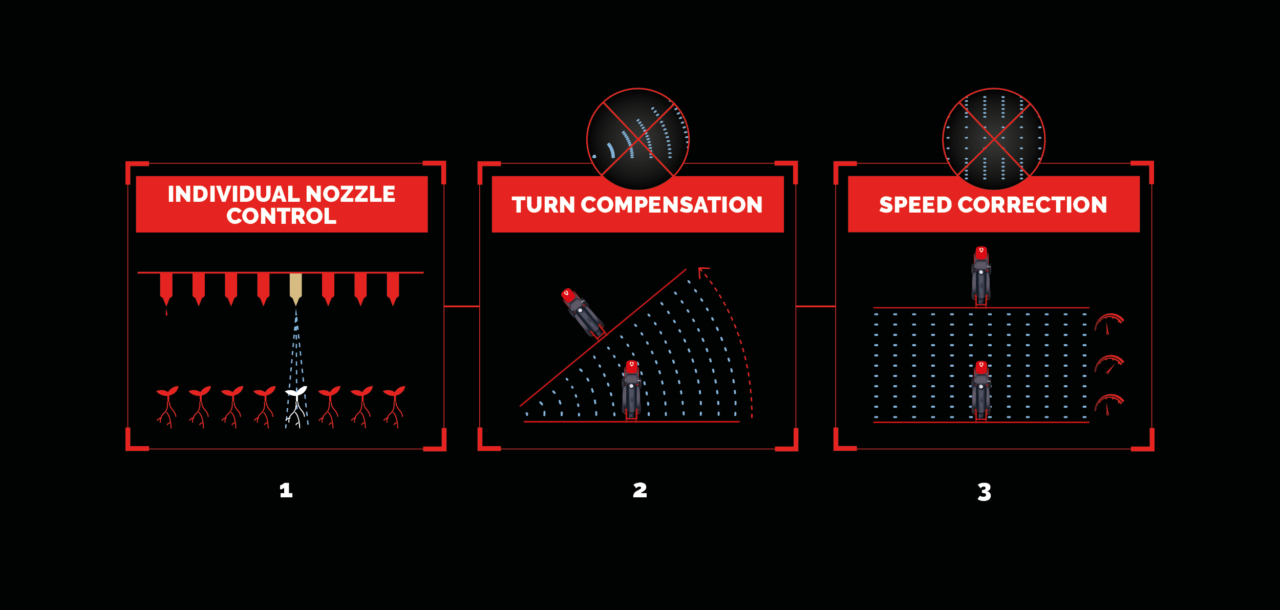

Three key features for precise application

1. Individual nozzle control: To prevent overlap and overdosing, each nozzle can be controlled independently. This allows precise application, reduces input waste and minimizes environmental impact.

2. Turn compensation: When turning, the nozzles on either side of the boom move at different speeds, the outer nozzles cover more ground, while inner nozzles cover less. To maintain uniform coverage, outer nozzles must spray more and inner nozzles less. StrictSprayPlus is a system that fully compensates for turns, ensuring consistent coverage across the entire boom, even in curves.

3. Pressure-independent speed control: In traditional systems, adjusting the spray volume means changing water pressure, which alters the flow rate, spray pattern and droplet size. With StrictSprayPlus, spray pressure remains constant, so your spray pattern and droplet size stay consistent, regardless of speed or flow rate. This ensures accurate, reliable application under all conditions.

StrictSprayPlus is available as an option on all Agrifac sprayers.